Band Heaters Regular

- Home

- Band Heaters Regular

- Products

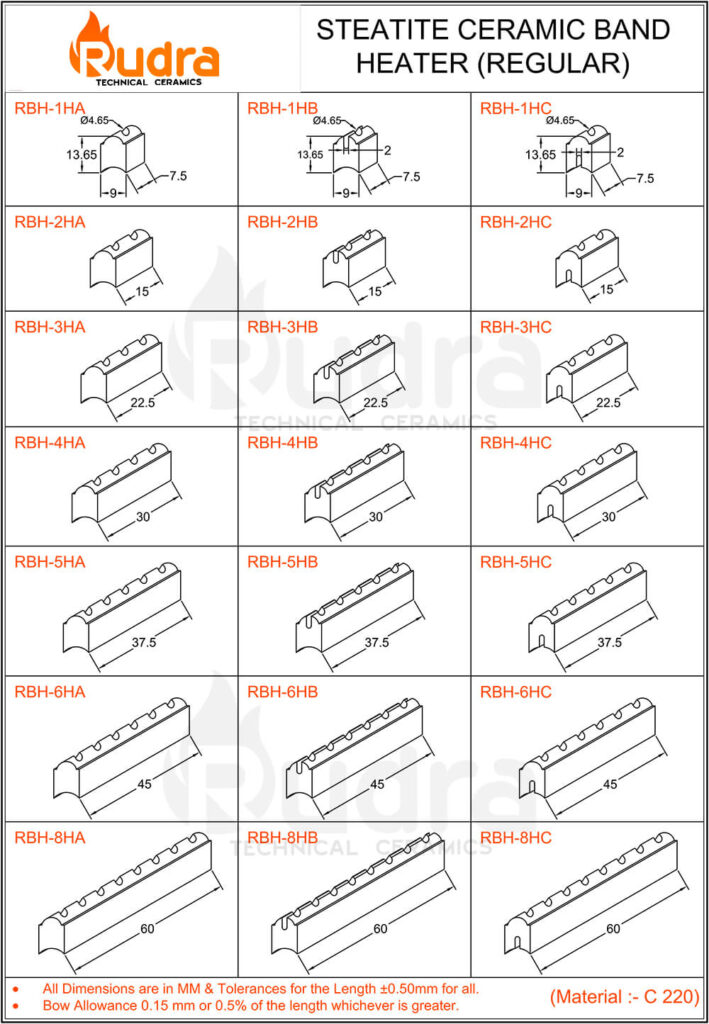

Rudra Band Heater Regular

Rudra Ceramics offers band heaters in different configurations, including the Band Heater B&C series. While specific details about this series are limited, band heaters in general are known for their durability and effectiveness in maintaining consistent temperatures across cylindrical surfaces.

Michael Ramirez

CEO Founder

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, non-metallic material, such as clay, at a high temperature. It is mainly manufactured from natural raw materials. The major components of the same are kaolin, feldspar, clay and soapstone. To enhance material properties such as high strength Zirconia and Alumina can be used.

Rudra Technical Ceramic manufacture a wide range of materials with excellent mechanical, electrical and thermal properties. As per IEC 60 672 our material classified in the following categories.

- Materials

Our Material Range

Porcelain (C-100 group)

Porcelain is the material that has a high mechanical strength, excellent electrical insulation properties, good chemical resistance, high dielectric strength and corrosion resistant. The main base of porcelain is quartz based silicate or alumina.

We manufacture the following grades:

- C112: quartz porcelain, shaped with wet pressing technology

Steatite (C-200 group)

Steatite is the material that has a high mechanical strength, excellent electrical insulation properties, low dielectric loss factor in high frequency range and high dielectric strength at room and high temperatures. The base of Steatite is natural raw materials and it consists mainly of soapstone.

We manufacture the following grades:

- C 220: alkaline steatite, shaped with dry pressing and extrusion technology

- C 221: non alkaline steatite, shaped with dry pressing, extrusion and injection moulding technology

Cordierite (C400 & C 500 group)

Cordierite is the material that has a high thermal shock resistance, high temperature resistance, low coefficient of thermal expansion and high specific resistance at high temperature. Cordierite is being made of alkaling earth aluminia silicates and porous alumina silicates.

We manufacture the following grades:

- C 410: nonporous cordierite material, shaped with dry pressing and extrusion technology

- C 510: porous cordierite material, shaped with dry pressing, extrusion and slip casting

Mullite Ceramics (C600 group)

Mullite ceramics is the material that has high mechanical strength, good electrical insulation properties, corrosion resistance and chemical inertness. The base of mullite ceramics is alumina silicates.

We manufacture the following grades:

- C 610: alumina porcelain, with high mechanical strength, shaped with extrusion and dry pressing technology.